M.E.S. can arrange reliable supply of feedstock gas suitable for processing into HDCNG®. This could be sourced from drainage gas or gas reserves in the miners own lease area, existing domestic pipeline supplies or proven but undeveloped reserves.

Alternatively, miners can supply their own gas from existing mine site infrastructure.

Diesel will continue to be sourced through traditional/existing supply arrangements.

Using patented High Density Compressed Natural Gas cylinder filling technology, processed gas will be compressed and filled into custom designed HDCNG® Fuel Packs containing fibre composite cylinders.

With all statutory approvals in place for use in the mining industry, the process delivers safe and effective cylinder filling resulting in a consistent fill every time. A level never before achieved allowing enough fuel to be carried on board for a full shift.

M.E.S. designed and purpose built road transport crates can be used to transport the HDCNG® ready for use to mining operations. This could be either where the feedstock gas is not available from within the lease area or where the gas processing site and the refuelling facility on the mine lease are some distance apart.

Pipeline options to transport low and high pressure feedstock gas to the processing train are also available where this is a more cost effective option.

M.E.S. offer a range of refuelling options including:

The non-invasive mine truck dual fuel conversion and tailored fuel pack configurations are supplied by M.E.S. and fitted by M.E.S. technicians.

A comprehensive development program is underway with the knowledge of the relative mine truck and engine OEMs.

This development program integrates M.E.S.' Electronic Fuel Control System with the OEM Engine Management Systems (EMS) ensuring optimum fuel control and performance.

The supply of mine site fuel is one of most significant cost inputs to any mining operation. HDCNG® diesel dual fuel conversion has the potential to reduce fuel costs by in excess of 25%. In some coal mining operations this can result in >AU$1 per tonne structural cost reduction.*

*Savings are directly reflective of supply costs of the gas feedstock (transmission line or mine drainage gas i.e. coal bed methane), size of fleet, extent of M.E.S. capital deployed. 25% is average for a large fleet (50+) large mine trucks with onsite gas feedstock availability.

No capital is required by the mining company to adopt the HDCNG® dual fuel system. The strength of the Sime Darby, Intelligas partnership allows for a fully funded capital model.

All capital required for gas transmission line connections or sub-surface gas gathering, processing, transport, handling and refuelling as well as on-truck and engine dual fuel infrastructure can be provided by M.E.S..

HDCNG® dual fuel delivers a reduction in the level of harmful diesel particulates commensurate with the achieved substitution rate i.e. 80% substitution directly correlates to 80% reduction in diesel particulates emitted.

Based on a conservative substitution rate of 70% of diesel with methane using M.E.S.' unique dual fuel solution, the following independently verified greenhouse gas (GHG) benefits are delivered with conversion:

The capture and use of fugitive methane contained in the coal resource to substitute diesel to fuel mine trucks enables many large coal mines to reduce their greenhouse gas footprint by more than 550,000 tonnes1 of CO2e per annum enabling significant steps to be taken in their decarbonisation journey without the need for midlife replacement of high value mining equipment.

The following extract from the Queensland Government's media statement of 6 January, 2022 supports those technologies such as M.E.S. Dual Fuel that can deliver a material and meaningful difference:

"The study... investigated opportunities to capture fugitive emissions from underground and open-cut coal mines in the Bowen Basin to assist in Queensland’s efforts to reduce greenhouse gas emissions... a big win-win for all involved."

The average Bowen Basin coal mine also receives >900 truckloads of combustible diesel per year to fuel the haul truck fleet and the adoption of M.E.S. dual fuel technology can reduce this by ~70% i.e. from 900 truckloads (17 per week) to 270 truckloads (5 per week) reducing the heavy vehicle pressure on public roads, further reducing emissions and improving road and community safety.

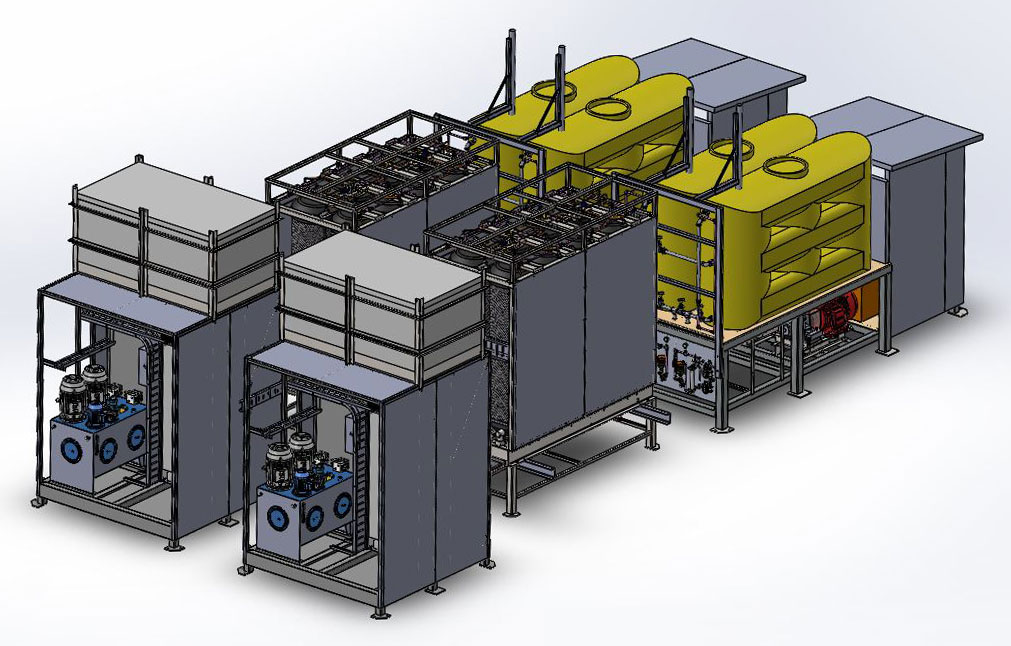

The process flow diagram shown here demonstrates the general arrangement to utilise on site waste mine gas as a replacement fuel for diesel.

Note1 - mass balance offset future vs current, includes discrete truck reductions + capture and use of mine site methane.

The use of methane as a reduced emission replacement for significant proportions of diesel in mobile mining equipment is proven and available for the current diesel powered global large mine truck fleet.

M.E.S. is now working on the introduction of locally produced zero emission hydrogen into the fuel gas stream to provide greater emissions reduction outcomes further assisting mine sites in their decarbonization journey.